Great performances, even in charging.

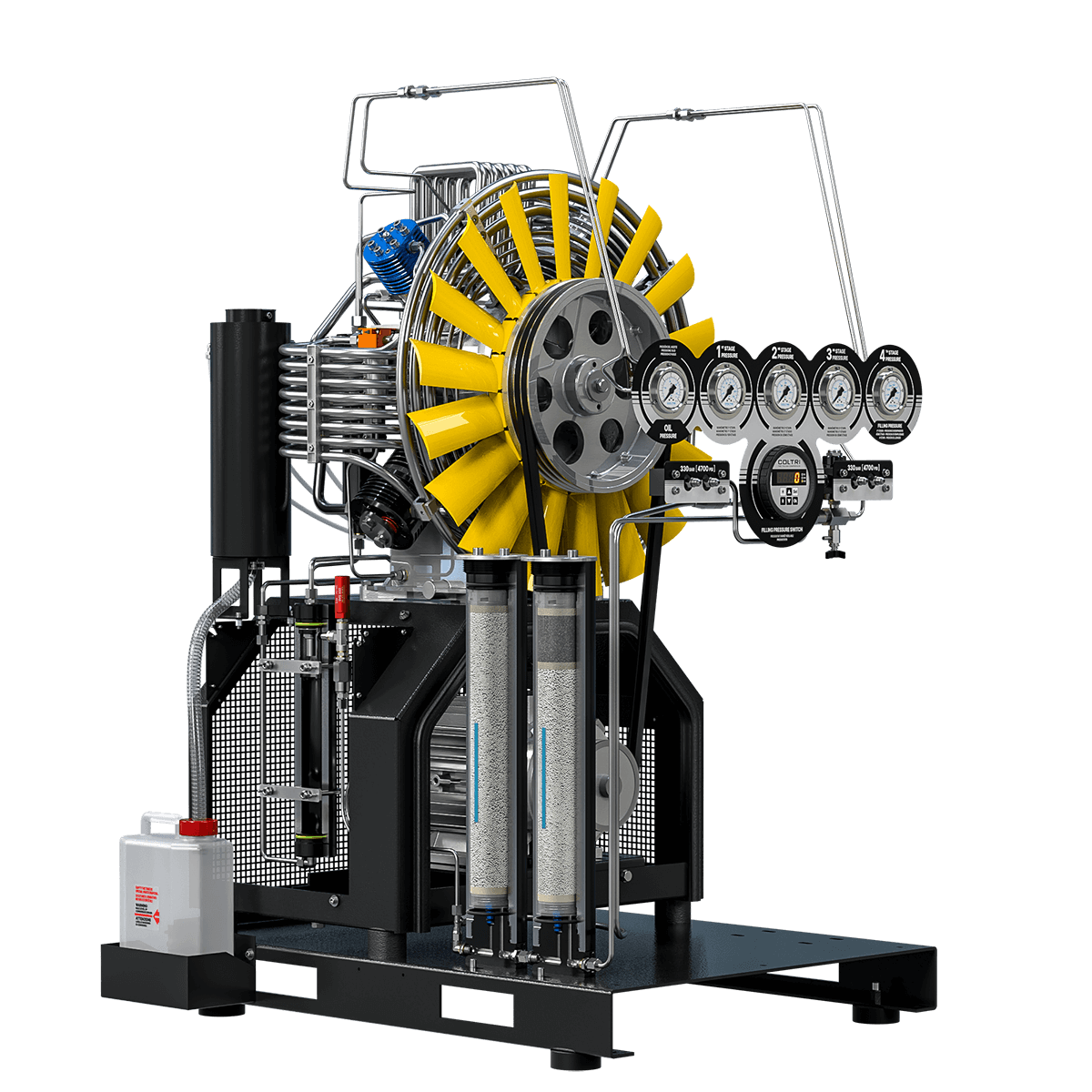

Open meets professional needs that require large charging capacities in hot, poorly ventilated or tropical countries. It is equipped with 4 front filling connections for high pressure hoses, an intuitive control panel and an electric motor. The pumping unit, chosen from the 4 most powerful, is exposed in the rear part of the structure to ensure a better cooling cycle. For longer filter life, the Tornado high pressure dryer is recommended. Available as optional: the Presec system for filter saturation control or the SAM system for multigas analysis and remote charging panel.

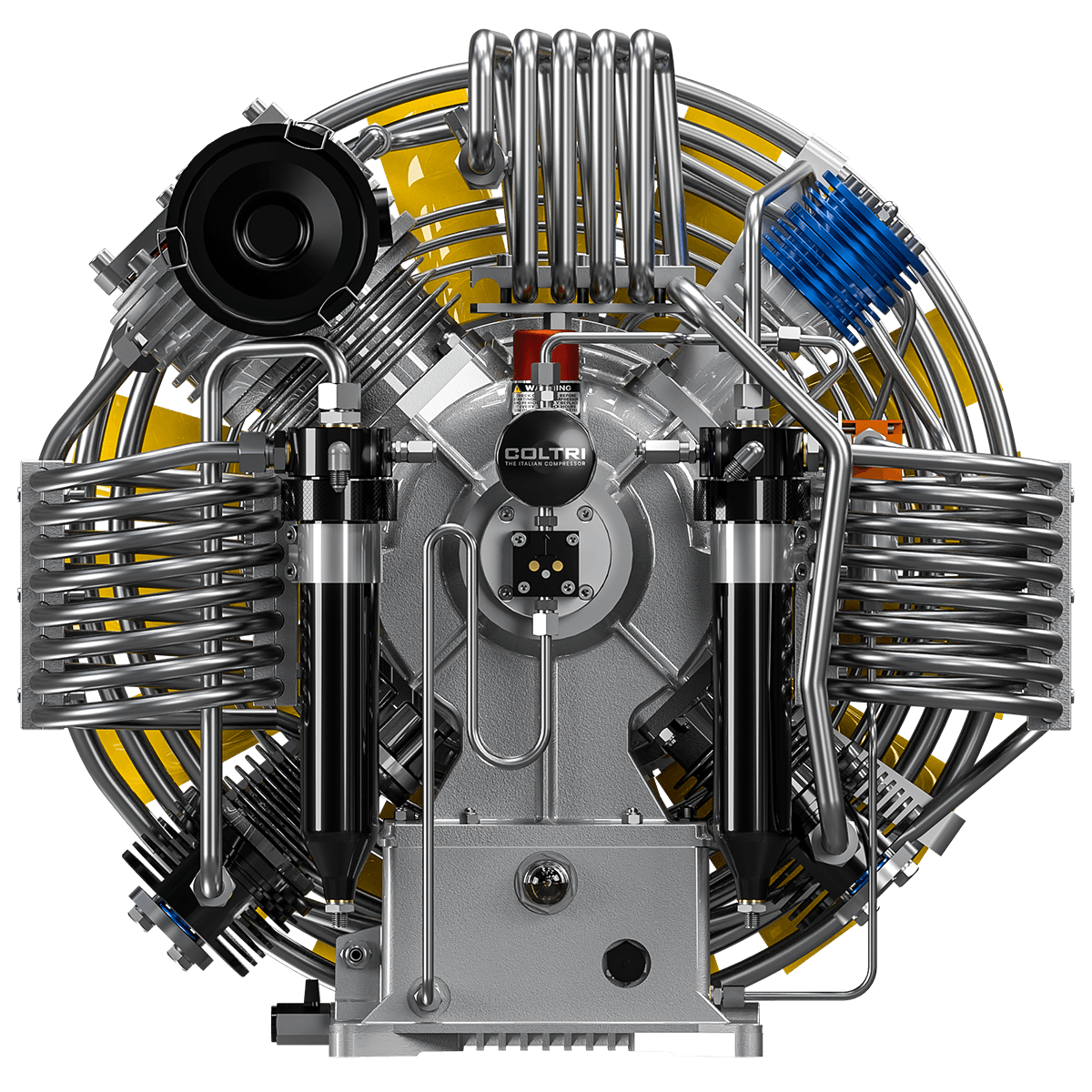

4-stage high pressure pumping unit.

- Monobloc in aluminum,

- Crankshaft in forged steel

- forced lubrication on the 4th stage cylinder by gear pump

- Oil filtration

- Aluminum connecting rods

- Main roller bearings

- Roller connecting rod bearings

- 1st, 2nd and 3rd stage cylinders in special cast iron

- 4th stage cylinder in special treated steel.

- Stainless steel intake and exhaust valves

- Interstage cooling pipes in stainless steel

- Separator after the 2nd, 3rd and 4th stage

- Safety valves after each stage

- Oil level sensor

- Prepared for Hyperfilter filter system

Purification at the highest level.

Placed after the last compressor separator and before the pressure holding valve, the Hyperfilter purification system enables reliable treatment of the breathing air according to DIN EN 12021¹ when using original filter cartridges. The separator present between the 2nd and 3rd stage of the purification circuit allows to extract the greatest possible humidity. The filtering capacity with inlet air at 20 ° C and 200 bar is 4300 m³.

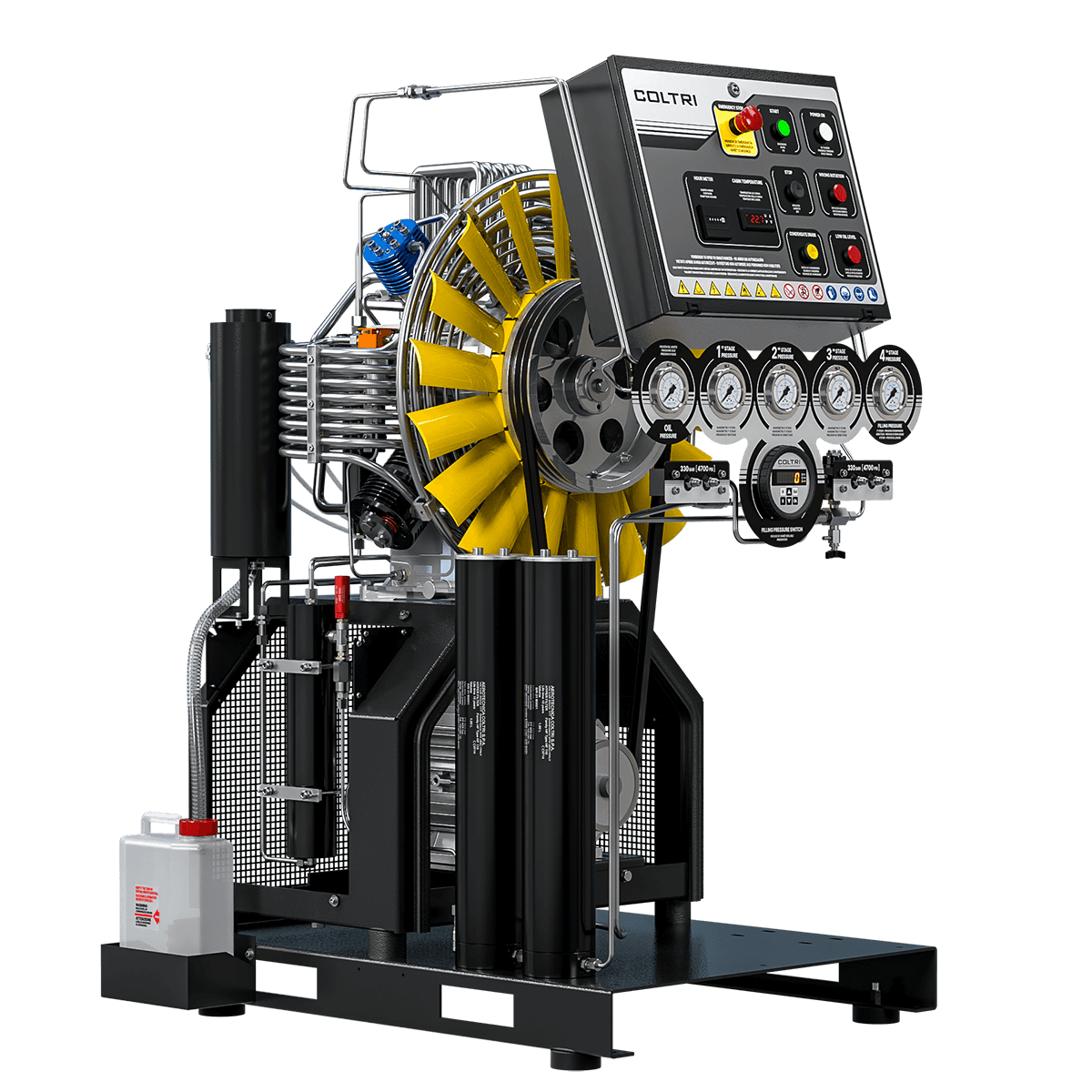

Electrical cabinet

- ON / OFF switch with motor protection switch.

- Digital electronic pressure switch that stops the compressor at the final pressure.

- Drainage of all separators between the individual stages and also of the final separator during compressor operation

- Timer for automatic condensate drain.

- Integrated no-load start (automatic drain every time the unit is switched off).

- 5 liter condensate collection tank, with silencer; capacity of about 3 liters, for the ecological disposal of condensate.

- Interstage pressure gauges display the working pressure for the individual compression stages. This pressure information allows you to check the tightness of the valves (inlet and outlet) of each stage and to quickly identify potential sources of failure.

Chassis

Open frame with vertical development designed to facilitate maintenance operations. The oil level and drain reported outside, the control console equipped with inter-stage pressure gauges, the oil pressure gauge, the internal temperature indicator, the presence alarm and incorrect phase sequence, the lack alarm oil and the start, stop and manual condensate drain commands allow easy management and maintenance of the compressor.

Simplicity comes standard.

Imagine having a compressor capable of great performance and endowed with extraordinary solidity.

What would all this be without absolute simplicity in managing it?

We believe that innovation is for this: to make everything simpler.

The highest air quality is the goal of a Coltri compressor.

Air purity and quality are two essential characteristics of our compressors. The air you breathe from Coltri compressors complies with the EN 12021: 2014 standards: this is why you can work, have fun and exercise with them in absolute safety.